Tuotetieto

Austenitic steels with designations 1.4301 and 1.4307 are the most common stainless types and contain 18% chromium and 8% nickel. The difference between the two grades is that in 1.4301, the maximum allowed carbon content is higher than for 1.4307 which can mean that 1.4301 has marginally higher strength. In practice, the difference in carbon between 1.4301 and 1.4307 is often of little significance. However, if welding is to be performed, 1.4307 is the preferred choice since with 1.4301 there is risk for impairment of corrosion resistance in the vicinity of the weld.

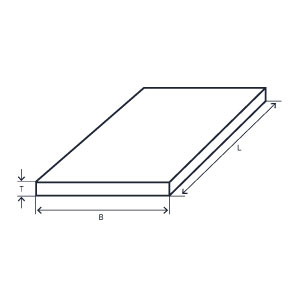

Flat formats of 1.4301/1.4307 are standardised in EN 10088-2. This standard covers cold-finished thickness up to and including 8 mm.

Grades 1.4301 and 1.4307 show good resistance to corrosion in neutral water both indoors and outdoors. The steels also exhibit immunity from atmospheric corrosion. However, stainless grades with higher alloy content will be needed if the environment is acidic or contains chlorides.

The formability of 1.4301 and 1.4307 in most cold-forming operations is excellent and often better than cold-rolled carbon steel. Both grades are also characterised by very good weldability and they seldom pose any problems in fabrication of welded structures.

For applications involving some degree of aesthetic consideration, Tibnor offers from stock cold-finished sheet in grades 1.4301 and 1.4307 in a number of surface finishes. Apart from 2R (bright-annealed and skin-pass rolled), sheet with various ground finishes, 2G and DP20, as well as a pattern-rolled execution, AN5, is available.